Pipe cladding is an essential process for protecting pipeline systems in Malaysia. Pipe cladding is the process of applying a layer of material to the external surface of pipes to provide protection against corrosion, abrasion, and other types of damage. In this article, we will provide a guide to pipe cladding made by unitrade berhad in Malaysia, its importance, and how it works.

What is Pipe Cladding?

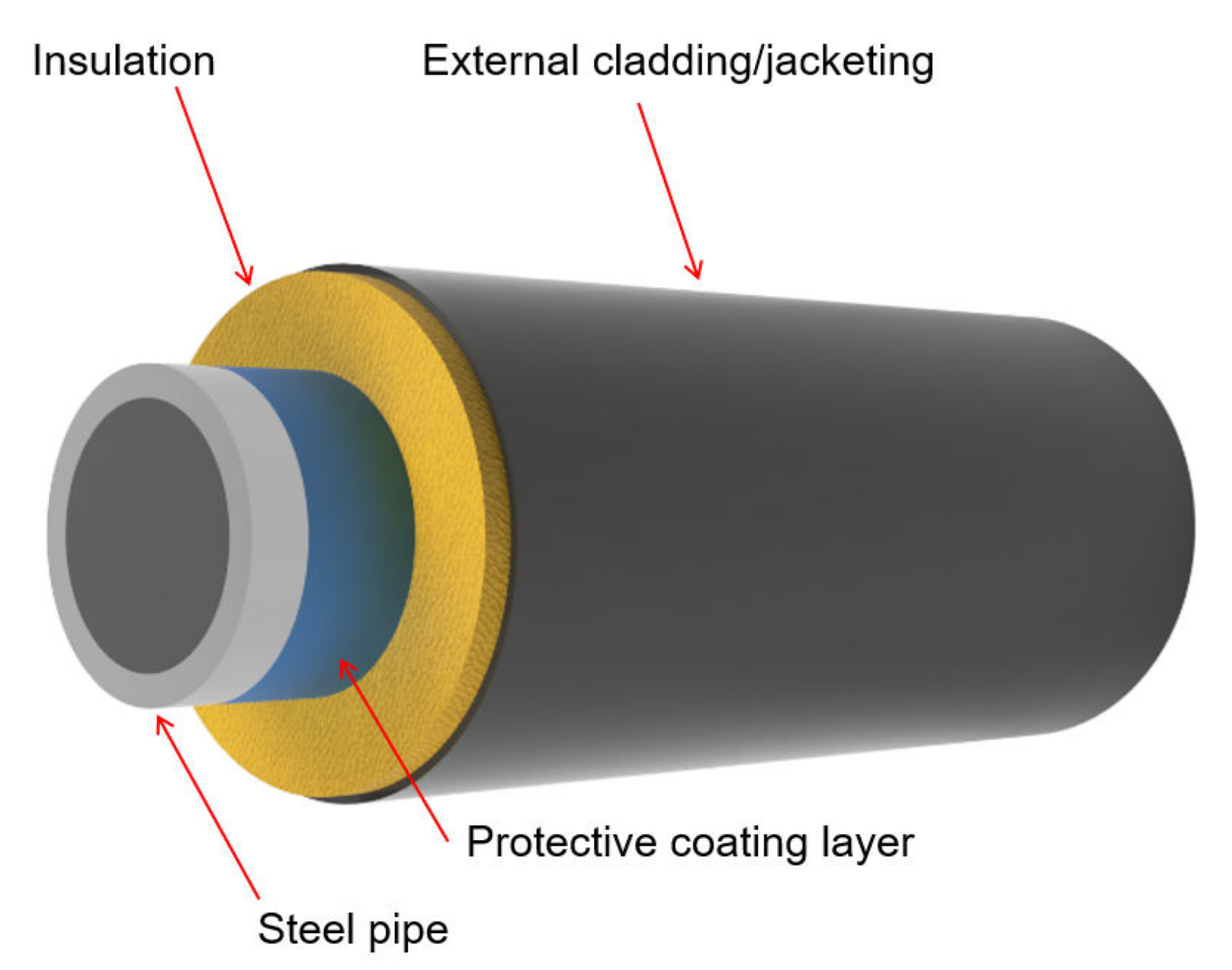

Pipe cladding is the process of applying a layer of material to the external surface of pipes. The material is designed to provide protection against corrosion, abrasion, and other types of damage that can occur over time. Pipe cladding can be made from a variety of materials, including metals, alloys, plastics, and composites.

How Does Pipe Cladding Work?

Pipe cladding works by providing a barrier between the external surface of the pipe and the surrounding environment. The cladding material prevents moisture, oxygen, and other corrosive elements from coming into contact with the pipe, reducing the risk of corrosion and other types of damage.

Pipe cladding can also provide additional benefits, such as thermal insulation and resistance to abrasion and impact. Some cladding materials can also provide color coding to identify the contents of the pipe or to distinguish between different types of pipes.

Importance of Pipe Cladding in Malaysia

Pipe cladding is important in ensuring safe and efficient operations of pipeline systems in Malaysia. Corrosion and other types of damage can lead to leaks, failures, and environmental damage, posing significant risks to the health and safety of workers and the public.

Pipe cladding can also provide economic benefits by extending the lifespan of pipeline systems and reducing maintenance costs. By preventing corrosion and other types of damage, pipe cladding can reduce the need for frequent repairs and replacements, leading to significant cost savings over time.

Types of Pipe Cladding in Malaysia

There are several types of pipe cladding available in Malaysia, including:

Metal Cladding: Metal cladding is commonly used in pipeline systems in Malaysia. It provides excellent corrosion resistance, durability, and high-temperature resistance.

Plastic Cladding: Plastic cladding is used for pipeline systems that require resistance to chemicals and environmental damage. It is also lightweight and easy to install.

Composite Cladding: Composite cladding is used for pipeline systems that require resistance to abrasion and impact. It provides excellent strength and durability, making it ideal for use in high-stress environments.

Applications of Pipe Cladding in Malaysia

Pipe cladding is used in a variety of industries in Malaysia, including:

Oil and Gas Industry: Pipe cladding is used in the oil and gas industry to protect pipelines from corrosion and other types of damage. It is also used to protect equipment and structures from environmental damage.

Water Treatment Industry: Pipe cladding is used in the water treatment industry to protect pipelines from corrosion and other types of damage. It is also used to protect equipment and structures from environmental damage.

Chemical Industry: Pipe cladding is used in the chemical industry to protect pipelines from corrosion and other types of damage. It is also used to protect equipment and structures from chemical exposure.

Conclusion

In conclusion, pipe cladding is essential in ensuring the safe and efficient operations of pipeline systems in Malaysia. Pipe cladding provides protection against corrosion, abrasion, and other types of damage, reducing the risk of leaks and failures. It also provides economic benefits by extending the lifespan of pipeline systems and reducing maintenance costs.

Leave A Comment