Introduction:

Valves control the flow of liquids and gases in almost all systems and activities. They can be found almost anywhere, including homes, companies, and hospitals. Choosing the right valve for the right job, despite how common they are, is a challenging undertaking. The performance requirements of the system dictate the valve to use. Here are five recommendations for selecting the appropriate valve.

- Check for Special Valves Requirements

Before you acquire a valve, make sure it will perform as expected. Consider how long it takes the valve to respond and how much pressure it takes to open it. You should also think about the differences between typically open and normally closed valves. The valve’s reliability can be improved by making the right choice. The choice is made based on whether the valve is more closed or open during regular system operation.

- How to Select the Right Valve: Materials of Construction

Valves are built of a variety of materials, each with its own set of properties such as strength and chemical resistance. As a result, you’ll need to know the valve’s strength and chemical compatibility. The liquids or gases going through a valve must not react with it. Plastic valves are the finest choice if you’re dealing with caustic or strong chemicals.

- Valve Type and Size

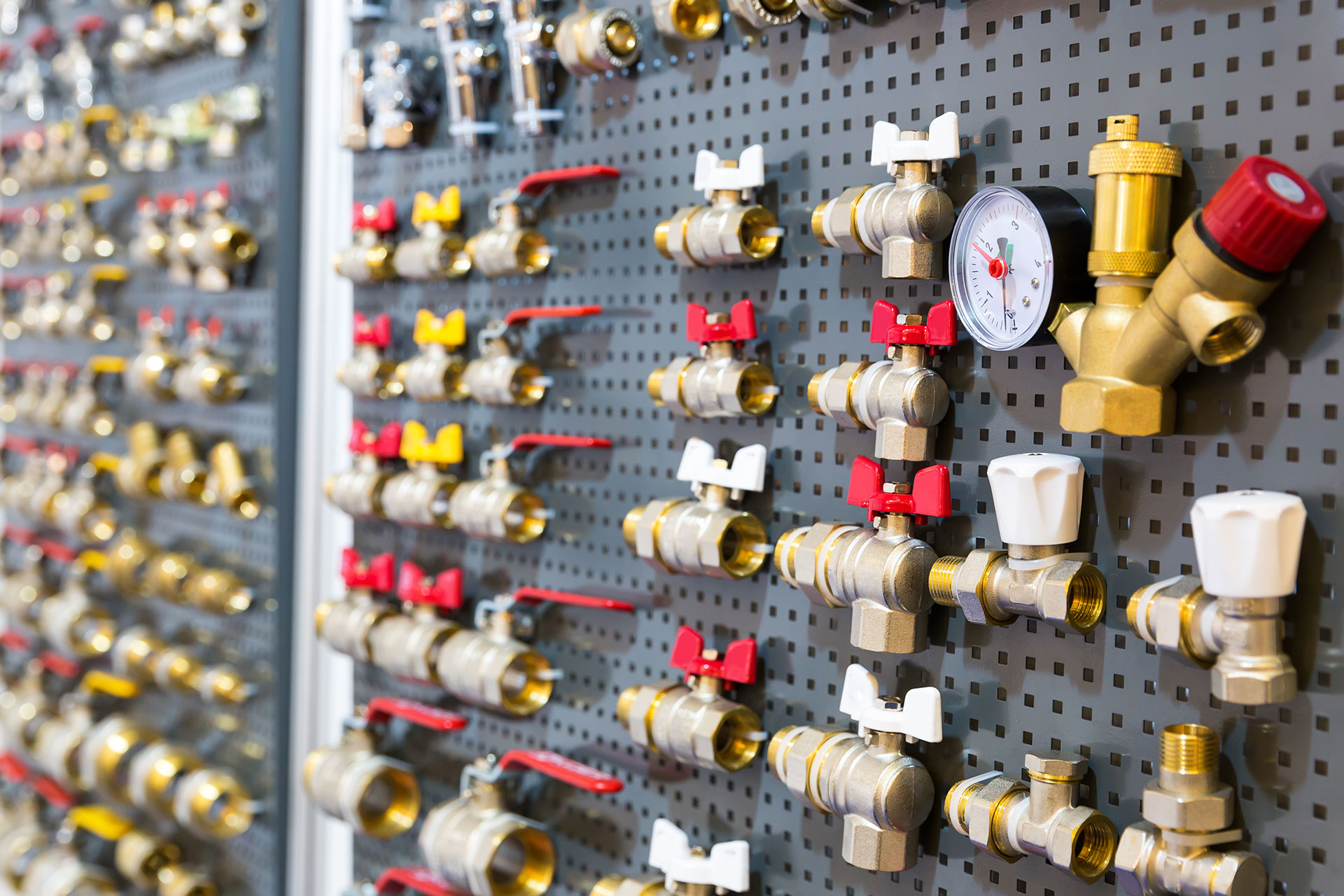

Valves occur in a range of shapes and sizes, which affects the applications they can perform. Valves can be used to control fluid/gas flow, mix flow, divert flow, and shut off flow. They can also be used to relieve pressure and prevent backflow. The type of valve to use is determined by the purpose of the valve. The most common types of valves are shut off valves, pinch valves, regulators, relief valves, stopcocks, toggle valves, metering valves, needle valves, ball valves, and check valves. Match the valve’s type and size to the system’s expected function to make the optimal option.

- Performance Requirements

A valve is supposed to function under a variety of temperature and pressure settings. A good valve should continue to function well at the system’s lowest and greatest temperatures and pressures. In highly pressurised systems, metal valves are preferable over plastic valves, especially if the operating temperatures are similarly high. This is due to the fact that metals are more durable than plastics.

- Maintenance

How to Choose the Right Valve It’s impossible to be comprehensive without taking into account upkeep. Because valves wear out over time, you must consider the expense of maintenance when selecting a valve. This is critical for application stability as well as valve dependability. Working with a defective valve is extremely hazardous since it might result in fluid or gas leaks. When selecting a valve, you should also examine the type of valve connection, since this has an impact on the speed and ease with which it may be replaced or repaired. Each connection type (Luer, push-in, barbed, threaded, and so on) has its own set of benefits and drawbacks.

Conclusion:

You must know where to begin in order to make your valve selection easier and faster. Having all of the facts can help you make a more confident decision. Before making a decision, you must first grasp concerns such as chemical compatibility and operating conditions of a valve, as well as the system’s application requirements. That concludes our guide on choosing the best valve.

Are you looking for a valve that fits your home? Take a glance at the pressure reducing valve Malaysia for more products available.

Leave A Comment